Why Conveyor Manufacturers Recommend Modular Design

Conveyor manufacturers have increasingly adopted modular design as the foundation of modern material handling solutions. Modular construction allows components to be built, arranged, and reconfigured with greater adaptability compared to fixed designs. This approach benefits packaging lines, pharmaceutical processing, food handling, and industrial automation, where changes in products, layouts, or compliance standards are frequent.

For this reason, conveyor manufacturing companies and conveyor suppliers consistently highlight modular equipment as a practical method for addressing industry-specific challenges.

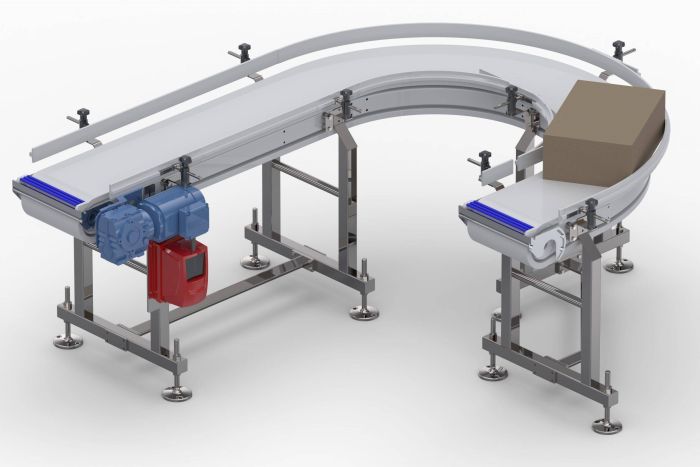

Modular conveyors are assembled from standardized building blocks that can be configured to meet specific line requirements. Unlike fixed structures, modules such as straight runs, inclines, curves, and transfers can be combined in countless ways.

This architecture provides flexibility for plant engineers while allowing components to be removed or replaced without disrupting entire lines. Conveyor manufacturers use 3D modelling and CAD-based engineering to pre-plan modular arrangements, which reduces lead times during installation and simplifies future expansion projects.

Manufacturing plants rarely remain static. New products are introduced, packaging lines are updated, and warehouse configurations are refined. Modular design addresses these realities by allowing for the quick reconfiguration of conveyors when floor space or line requirements change.

For example, conveyor manufacturing companies can add a new curve or transfer section without having to redesign the entire structure. Conveyor suppliers often provide modular kits that integrate seamlessly with existing installations, reducing downtime and giving production managers confidence in adopting layout changes.

Maintenance and upgrades represent significant cost considerations in material handling. Modular conveyors simplify these processes by allowing isolated replacement of parts. If a chain, guide rail, or motor requires service, the affected module can be swapped without needing to dismantle the entire system.

This reduces downtime, improves plant safety, and helps extend the equipment's lifecycle. Many conveyor manufacturers offer standardized spare parts across their modular platforms, making procurement faster and more efficient for plant operators. Maintenance teams also benefit from straightforward training, as the design is repeated across modules.

The adaptability of modular conveyors makes them suitable for a wide range of industries:

- Food and Beverage: Hygienic modules built with stainless steel or plastic materials for washdown environments.

- Pharmaceutical: Cleanroom-compliant designs with retractable sections and smooth transfers for delicate packaging.

- Agriculture: Configurable layouts for transporting trays, produce, and packaged goods across varying plant conditions.

- Manufacturing: Heavy-duty modular sections designed for mixing, assembly, or palletizing applications.

- Warehousing and Distribution: Scalable designs that accommodate sortation, merging, or spiral chutes for vertical transitions.

By offering modules suited to each industry, conveyor suppliers meet both technical requirements and compliance standards.

How Conveyor Suppliers Implement Modular SystemsImplementation of modular conveyors typically follows a structured process:

- Assessment of Requirements – Product types, weights, and environmental considerations are analyzed.

- Design with Modular Sections – Straight runs, inclines, and curves are combined into a digital layout, allowing for seamless integration.

- Integration with Other Equipment – Modules are designed to align with packaging machines, inspection devices, or robotics.

- Installation and Training – Pre-engineered modules are installed quickly, and plant staff receive training on operation.

- Long-Term Adjustments – As production demands change, modules are reconfigured or upgraded with minimal disruption to ensure ongoing efficiency.

This process highlights why modularity has become the standard recommendation from conveyor manufacturing companies worldwide.

Modular Design as an Investment in AdaptabilityUnlike conventional fixed conveyors, modular construction acts as an investment in long-term adaptability. Equipment remains useful even as industries adopt new products, adjust to market demand, or comply with emerging regulations.

Flexibility in design reduces the total cost of ownership and allows businesses to maintain productivity while adapting infrastructure incrementally. The modular concept demonstrates why conveyor manufacturers promote this design philosophy across so many sectors.

Modular conveyors offer several measurable advantages, including enhanced adaptability, reduced maintenance requirements, and improved performance in specific industries. Plant operators gain systems that can adjust as production requirements evolve, while manufacturers benefit from standardized components and simplified service.

Conovey designs and engineers automated material handling equipment that incorporates modularity at every stage. To learn how an industrial conveyor manufacturer can help optimize automation projects with modular design, connect with Conovey today.