Revolutionizing Industrial and Commercial Water Filtration

In the realm of liquid filtration, Ceramic membranes stand as a beacon of innovation and efficiency, offering unparalleled performance in water treatment, oil and water separation, and wastewater management. These artificial inorganic membranes, crafted from materials like alumina, zirconia oxides, and silicon carbide, have redefined the standards of filtration technology with their exceptional properties and versatile applications.

Unveiling the Marvels of Ceramic Membranes

Ceramic membranes represent a leap forward from traditional polymeric membranes, offering superior resistance to aggressive media and chemicals. This unique characteristic makes them ideal for a wide range of industrial applications, including water treatment, oil and water separation, Grey water treatment, and Sewage water treatment. Unlike their counterparts, ceramic membranes exhibit thermal stability, chemical stability, and long-term durability, making them the preferred choice for demanding filtration tasks in industrial environments.

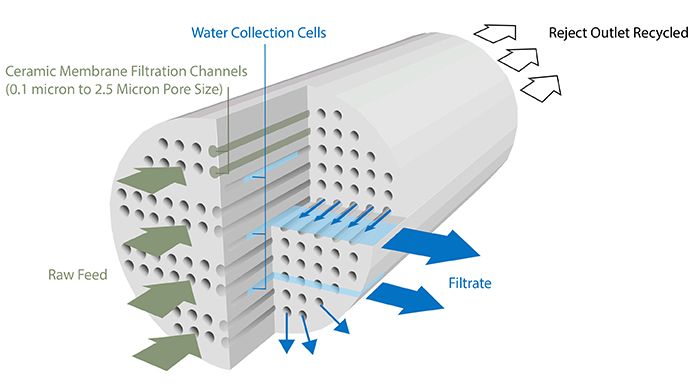

The Mechanics of Ceramic Membrane Filtration

At the heart of ceramic membrane filtration lies a sophisticated process that separates impurities from liquids with precision and efficiency. As the feedwater enters the ceramic membranes, a series of filtration mechanisms come into play. Suspended solids, particles, oil droplets, emulsions, bacteria, and other contaminants are effectively removed, leaving behind pure and clean fluid.

The filtration process encompasses various stages, each tailored to address specific contaminants and achieve desired filtration levels. Microfiltration and ultrafiltration target suspended solids, colloids, viruses, and other microscopic impurities, while nanofiltration and reverse osmosis focus on removing salts and ions.

Advanced Ceramic Membrane Filtration: A Technological Marvel

In recent years, advancements in ceramic membrane technology have propelled liquid filtration to new heights of efficiency and effectiveness. Industrial liquids undergo a comprehensive filtration process, facilitated by advanced ceramic membranes, which ensures the removal of even the finest impurities.

The ultrafiltration method, enabled by high-quality ceramic membranes, is particularly noteworthy for wastewater treatment. By effectively removing bacteria, viruses, oil emulsions, synthetic dyes, and other contaminants, ceramic membranes play a pivotal role in optimizing industrial operations and promoting environmental sustainability.

Embracing Sustainability for a Cleaner Future

As concerns about water scarcity and environmental pollution continue to mount, the importance of effective liquid filtration cannot be overstated. Ceramic membranes offer a sustainable solution for addressing these challenges, providing a reliable means of treating grey water, sewage water, and industrial effluents.

Moreover, the recyclability and longevity of ceramic membranes further underscore their sustainability credentials, making them indispensable tools in the quest for cleaner water and a healthier planet.